Climate change action

Saying that climate change has been a big topic of conversation over the past few years is an understatement! We’ve seen activist Greta Thunberg encouraging people to take immediate action with her speeches and campaigning. We’ve seen Extinction Rebellion going to great (and sometimes controversial) lengths to raise awareness of an environmental emergency. David Attenborough has also spoken about how much the world has changed through his well-loved documentaries. Worldwide meetings such as the Paris Climate Agreement and COP22 have showcased these concerns on the global stage.

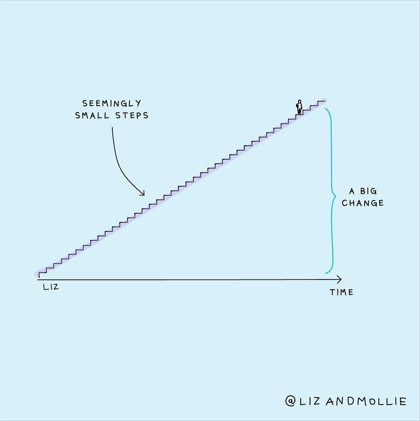

It can be difficult to understand what your impact is as an individual, a consumer or a business. Some may say that one individual taking action isn’t enough. However, what all the above is really about, is bringing everyone together. As Liz and Mollie (illustrators and writers) show in their graphic, lots of little changes can amount to one big change.

Credit goes to @lizandMollie on Instagram

The role of businesses in climate change

SMEs make up 90% of businesses worldwide, meaning that if they come together to make changes, it really can make a huge impact.

María Mendiluce, CEO of the We Mean Business Coalition explains, “Together, these small businesses have a huge impact – both on the planet and on their communities. To limit the effects of climate change, and to create a just future that leaves no one behind, it’s imperative that every business, of every size, has the tools they need to prioritise climate action.”

Many SMEs will already be considering climate change in their business plans. However, research from SME Climate Hub found that of those interviewed, “two-thirds of small business owners are worried they don’t have the right skills and knowledge to tackle the climate crisis”.

With that in mind, here’s what we’re currently doing at Fireco to reduce our impact on the environment.

Operations

Starting with some of the easier swaps to encourage less waste, we have water machines to refill cups and bottles, a big refill box for our washing-up liquid and we’ve introduced plastic-free drink options in our fridges for when guests visit us.

When we do need to buy items we try to choose things made from recycled materials, such as paper towels, kitchen rolls and printer paper. Or, at the very least, recyclable, such as coffee pods.

We’ve recently been undergoing an office makeover and even during this process have had the environment firmly in mind. All the ‘new’ furniture in our canteen is actually second-hand. Our old furniture was donated to charity or put on Facebook Marketplace so that nothing needed to go to the tip. We are also trialling vinyl covers for our desks as a way of upcycling them.

Marketing

The first thing our Marketing Team wanted to change was the branded merchandise, e.g. pens, bags etc.

Our reusable coffee cup and coaster are made in the UK from recycled materials.

So far merch-wise:

- We’ve stopped buying mugs

- Plastic bags have been replaced with tote bags from an ethical factory,

- Plastic flasks have been swapped with coffee cups made in the UK from recycled materials and they’re recyclable

- Our new coasters are from the same UK factory and are made from recycled materials.

- We’re currently looking at pen options.

We’ve stopped printing and stockpiling leaflets, and instead, print only what is requested.

We also explain to our suppliers what we’re trying to achieve and in doing so have reduced waste and even saved money. For example, we reuse the bags and frames from our pull-up banners and we also try to repurpose bits of our bigger event stands.

The Marketing Team spreads the word about what we’re doing! It can encourage and inspire people to make changes too and allows customers to make more informed choices.

Vehicles/travel

Burning fossil fuels e.g. petrol is said to be one of the main contributors to global warming, which is why looking at the way we travel to work is also so important in our efforts. We’ve already implemented a cycle-to-work scheme and provided a safe bike storage area.

The latest element is looking into our company vehicles. Where feasible, we’re swapping our current cars for hybrid cars and we’ve provided an electric car charging point at our office for staff to use.

Products

An unpacked Dorgard Pro. We use as little plastic as possible in our packaging!

The largest part of our business is manufacturing. We design, engineer and assemble everything in-house. There are so many elements to building products and with the uncertainty in the supply chain, it’s ever-changing! That said, it’s still totally possible to make positive and achievable improvements.

To help lower the carbon footprint of our products, we aim to source as many of our parts as possible from the UK. We still source parts from China, where necessary. For example, 90% of our 42 unique DorMag parts are sourced within the UK. To help us track the environmental impact of our components, we have launched ‘The life cycle analysis’. We analyse the product life span and build an understanding of what stages the product goes through. This information can help us make better decisions when sourcing future components. You can read more about this here.

Our products are designed to last and be fixable. We don’t manufacture throw-away-and-replace products. If a product is over 5 years old and can’t be fixed, we will recycle as much of the product as possible.

A maintenance plan is also available for customers, which means we’ll go out to their site and keep products in good working order, or repair them where necessary.

As part of our new fire door installation service, we’ve organised all old fire doors to be broken down, with metals going to recycling and wood being made into biofuel. This is included in the service and comes at no extra cost to the customer. As yet, we haven’t found a way to recycle fire-resistant glass – do you have any tips for us?

Packaging

It’s not just about the product, it’s also about the packaging! This is possibly one of the easiest swaps to make if you’re aiming to reduce plastic waste

So far:

Some of our packaging in the manufacturing area.

- All of our products come in a cardboard box, custom-fitted to the product to reduce excess packaging

- Our void fill is scrunched up brown paper

- We reuse bubble wrap and other protective layers that have come in from our suppliers

- Pallet wrap is made from sugar cane

- ‘Docs enclosed’ wallets are paper

- DPD bags are made from recycled materials

We’re not stopping there! Research is already being carried out about paper tape and better alternatives to screw bags.

This is just the start of our journey to become a more environmentally friendly company. The changes we’ve made so far are recognised and celebrated around the whole business and we know that with our dedicated team on board, we can go even further.

If you’ve made any changes in your business, we’d love to hear about them! Please reach out to us at environment@fireco.uk or leave a comment.

0 Comments